Welcome to Matus1976's Akira Bike Project - Building a fully functional high performance recumbent motorcycle inspired by Kaneda's ride in "Akira"

Update 20

On to the detailed update - Last we left off was with the completion of the updated stiffer virtual pivot point assembly. With the move pending, I wanted to get my chassis rolling, to start with I had to build an alignment jig. Starting off with four 12' 2" x 4" steel beams, I begin chopping

Cutting on the chop saw. A band saw would be better, but I don't have a large one

Post cut. These were thick cuts and took a bit of time

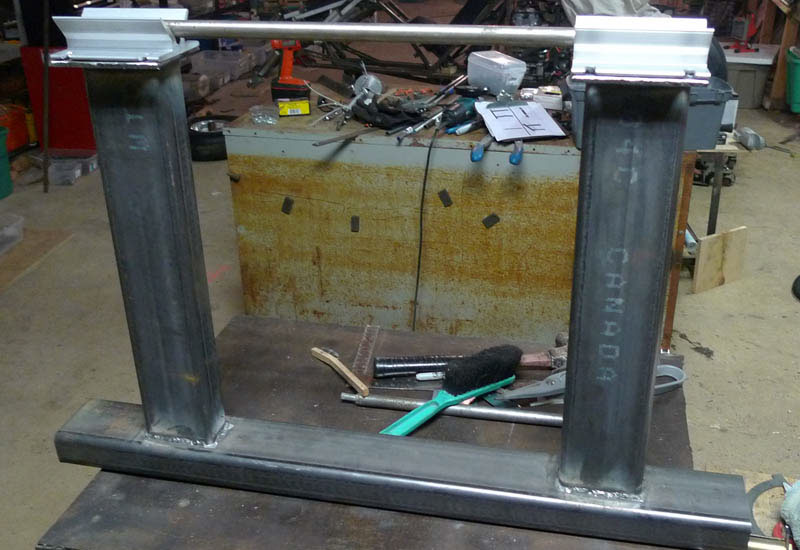

It is necessary to use large stiff beams for frame jigs and alignment jigs as they must resist the twisting caused by the welding of the bike assembly. Here we see a few cuts later. This is the base and the vertical legs for a front end alignment post, at the top of the legs two rectangles are cut with the plasma torch

These are welded to the top of the legs and V-Blocks are attached.

This whole assembly will hold the front spindle straight with respect to the rear spindle

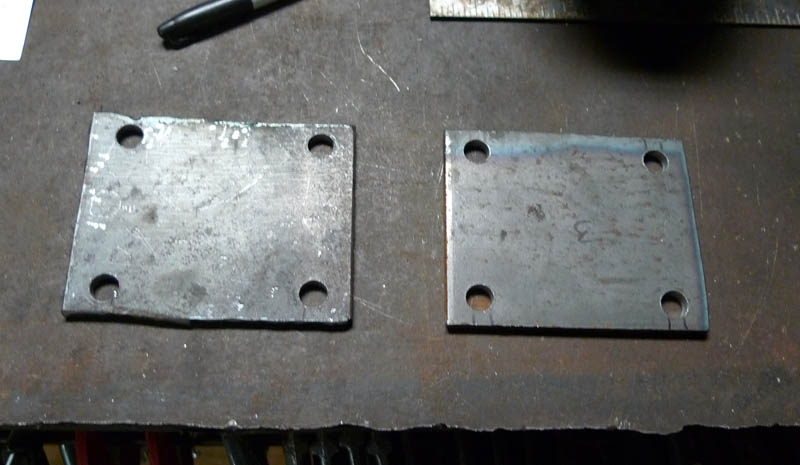

The plates are drilled:

And the final assembly is aligned and welded

The front end sits in this assembly like this

And here you can see the front end with brake calipers and rotors. This assembly made aligning the components of the front end much easier.

The rotor mounts required some especially careful alignment, which I won't bore you with. The end result of the central hub with brake rotor mounts is below.

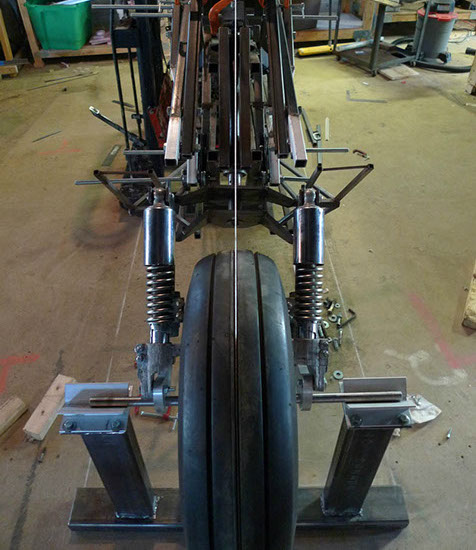

And here is the front end, straight on, where you can clearly see the leading links and brake calipers

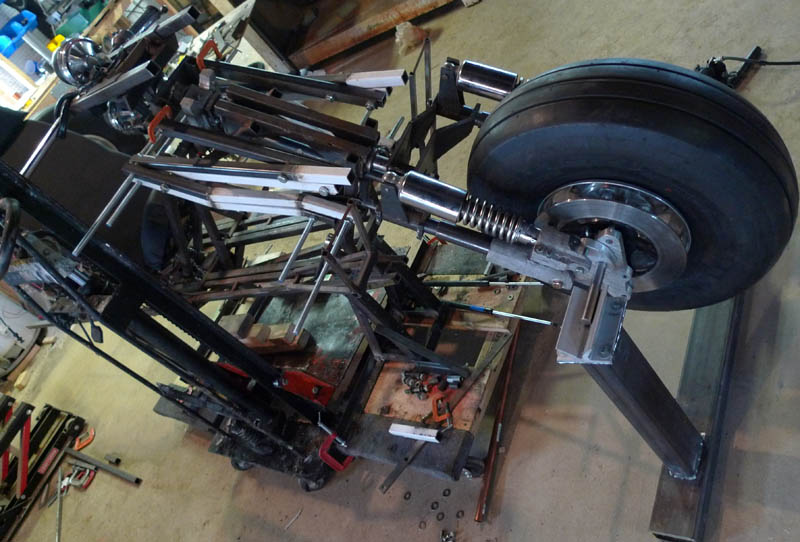

Lifting the bike and putting the front end on we see this. Here you can see the spindle resting in the V-Blocks of the front alignment jig

And now with the wheel on (actually there were many many steps between these two events that were all based on trouble shooting problems with the front end as well as trying to lift / hold the bike while putting the wheel on)

A closer view

And a side view

Next we are on the to rear wheel alignment jig, after much cutting, aligning, and welding we have the following:

In this case the spindle is a much larger diameter (2 1/4") for reasons you'll see later, the small cups on the end are aluminum pieces with a groove machined into the to relieve the edge of the spindle, then the whole thing has a 3/4" rod going through it to mark the center Here is the rear wheel on the spindle on the alignment jig

For starters a string is placed at the center of the front and rear wheel and along the centerline of the bike, it makes noticing misalignments much easier.

View from the rear wheel, after tweaking and tapping we see we have a pretty good alignment.

And from the front, pretty good as well.

Rear alignment

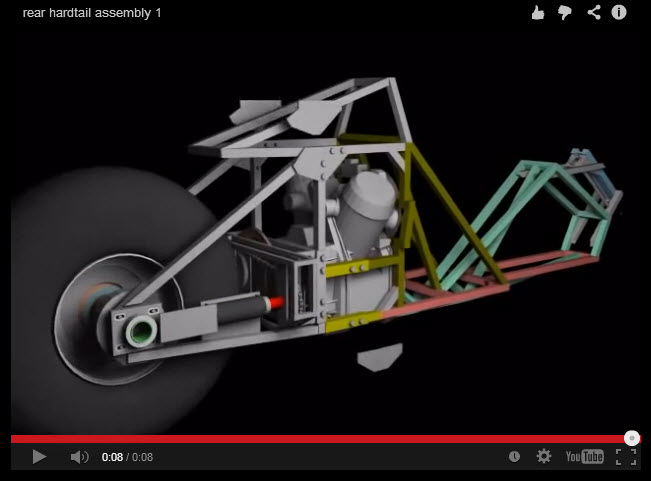

The next part then is to permanently attach the rear spindle and wheel to the bike. Well not permanently, as I noted before, the whole rear assembly will be easily removable to facilitate trouble shooting / upgrading / modification etc. https://www.youtube.com/watch?v=H0ZVDBYppYU

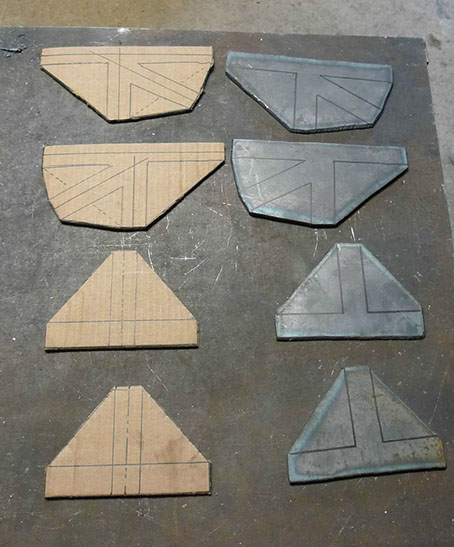

The plates to be cut are then traced out of cardboard

And then cut with the plasma torch out of 1/4" steel plate

Marked and getting ready for drilling

Accurately marked and center punched

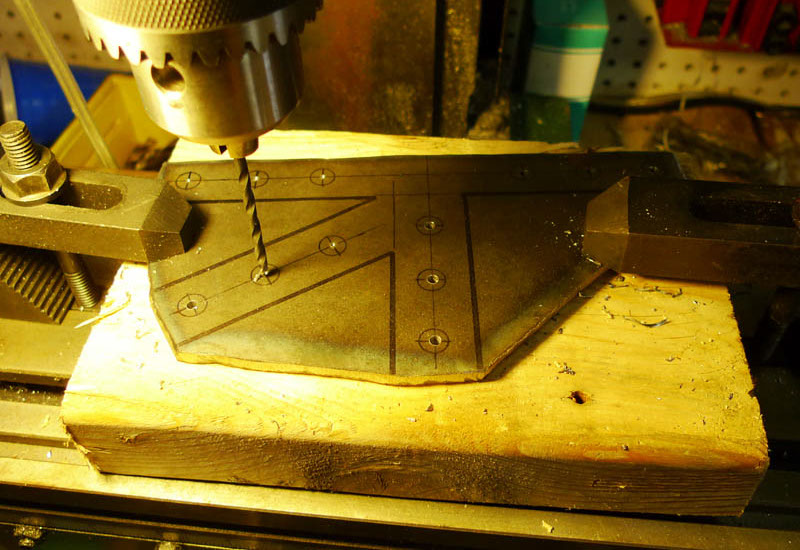

Drilling commences

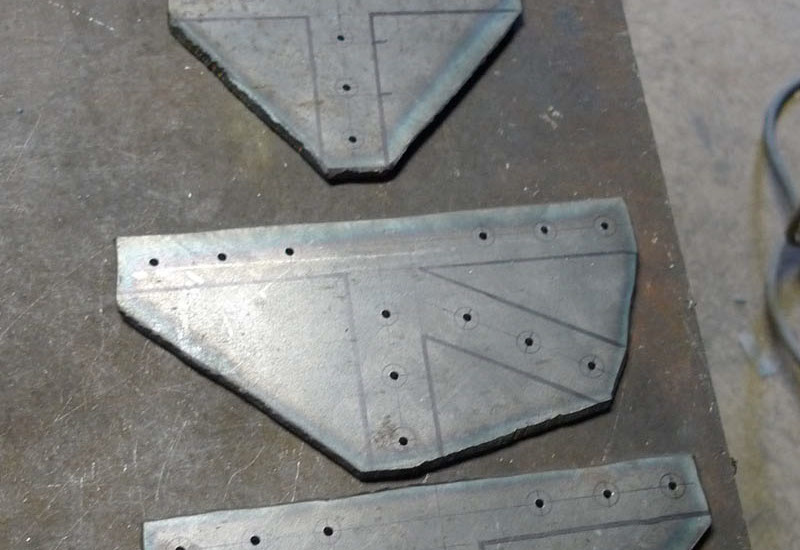

All pilot holes now drilled

Getting ready to drill the frame tubes

The frame tubes are marked and getting ready for drilling

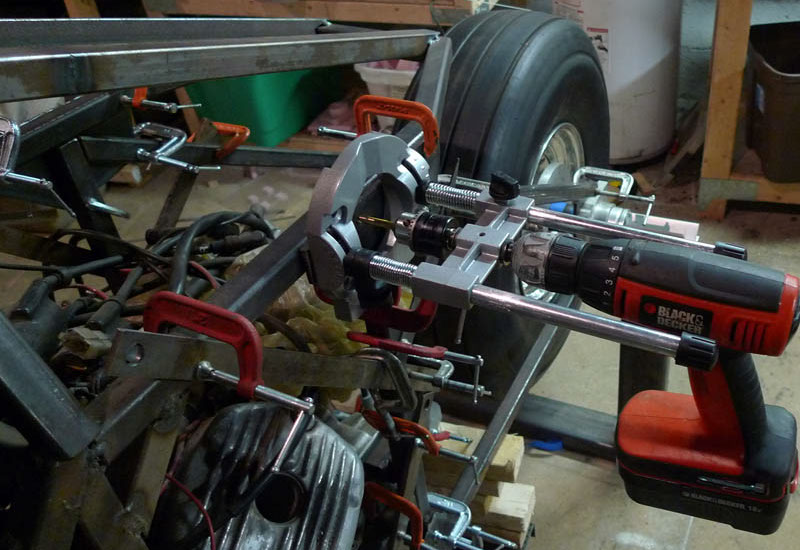

It was absolutely necessary to clamp a drill guide to the plates and use the plate and drill guide to force the drilling through the frame to stay in alignment. This was a very tedious operation and the holes took serious effort.

A good drill right through to the other side

The first couple holes are now drilled and 1/4" grade 5 bolts placed through them.

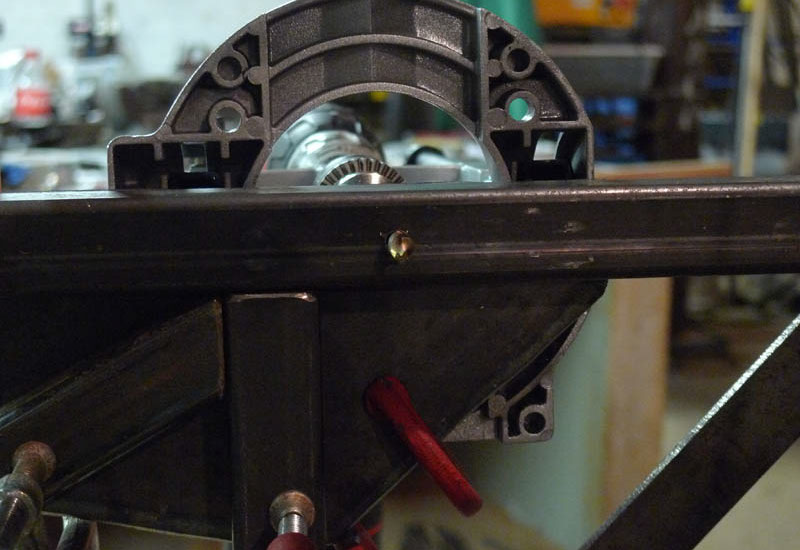

All the holes of the first plate completed!!

I should note these plates are not an optimal design, really you shouldn't have sudden changes in thickness like these plates produce, those sudden changes produce stress concentrations and become the points of fatigue failure. But in this prototype I won't see enough mileage to worry about fatigue failure and I am not overly concerned with weight. Ideally, gussets like these would transition smoothly in a curve from one tube to the next.

A nice view from the other side. These holes took serious work to drill so I must show off a few extra pictures!

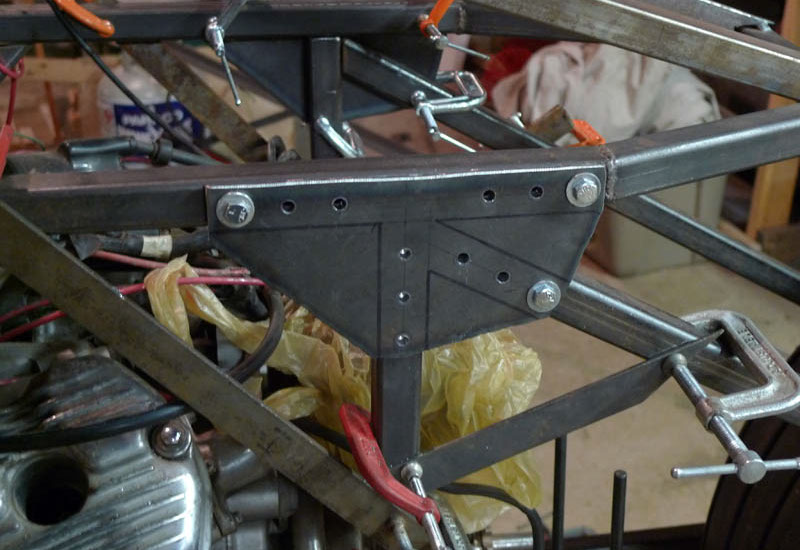

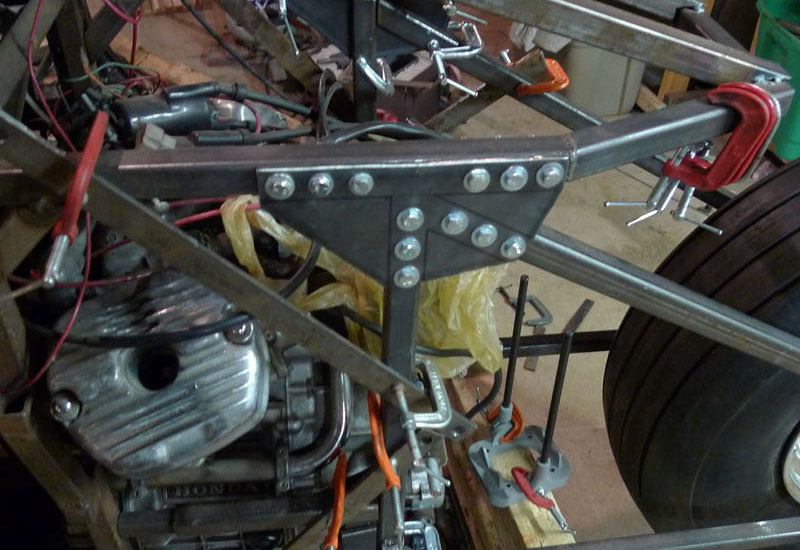

The left side now completely drilled and bolted.

Right top completed

And right bottom completed... All done!!!!!!!

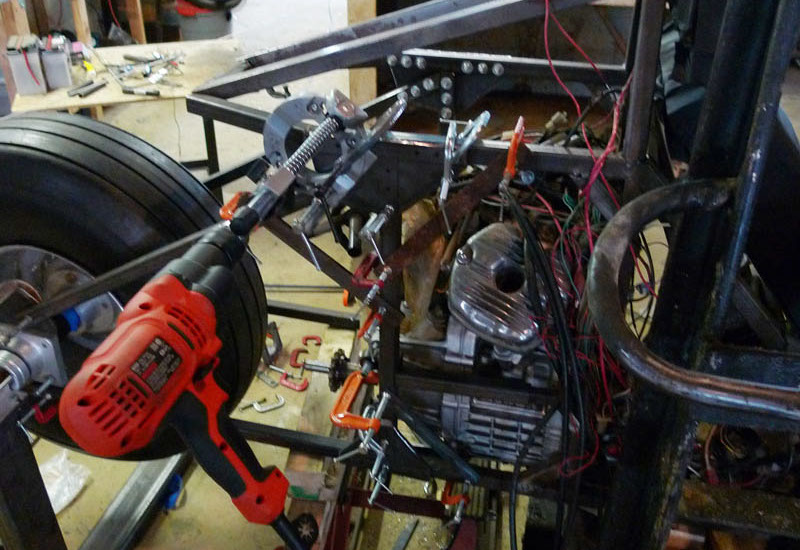

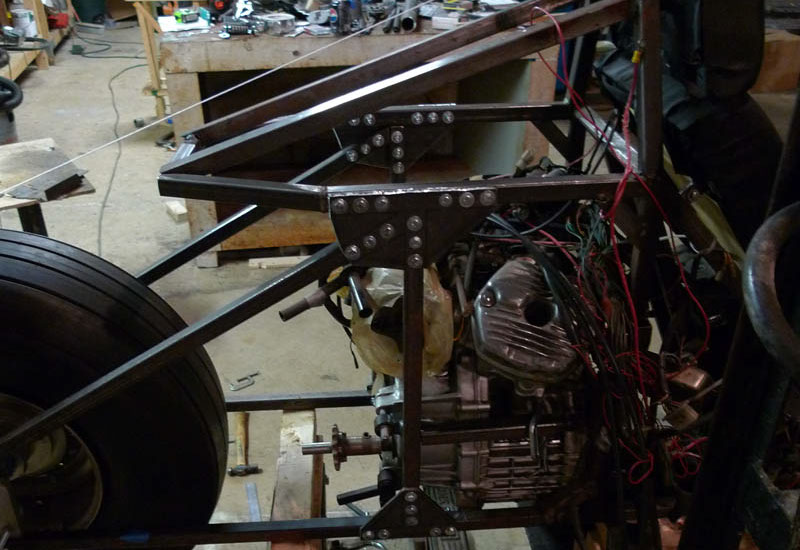

With those plates bolted and the ends of the tubes welded to the rear spindle mounts, this is the first time the front and rear axles actually supported the weight of the vehicle!

And lowered to the ground... Such a proud moment! My baby's first steps.

Numerous rolling chassis pictures commence

Rolling Chassis

Rolling Chassis

Rolling Chassis

Rolling Chassis

Rolling Chassis

Rolling Chassis

That's all for now, I won't bore you with details of the move, but next update will be from Seattle!

Check out a video of the rolling chassis https://www.youtube.com/watch?v=Et2uQBayVmc

1 - 51

<

>

As the move to Seattle approaches, I rushed to get my Rolling Chassis completed and to get my shop packed up, check out completion of an unpowered rolling chassis, the hard tail rear frame mounting plates, and the first videos of a rolling chassis

Help bring the fully functional high performance production Akira inspired motorcycle into existence...

Contribute through Amazon affilicate purchases

Donate directly

go to crowdfund for more options

send donations to