Welcome to Matus1976's Akira Bike Project - Building a fully functional high performance recumbent motorcycle inspired by Kaneda's ride in "Akira"

Update 19

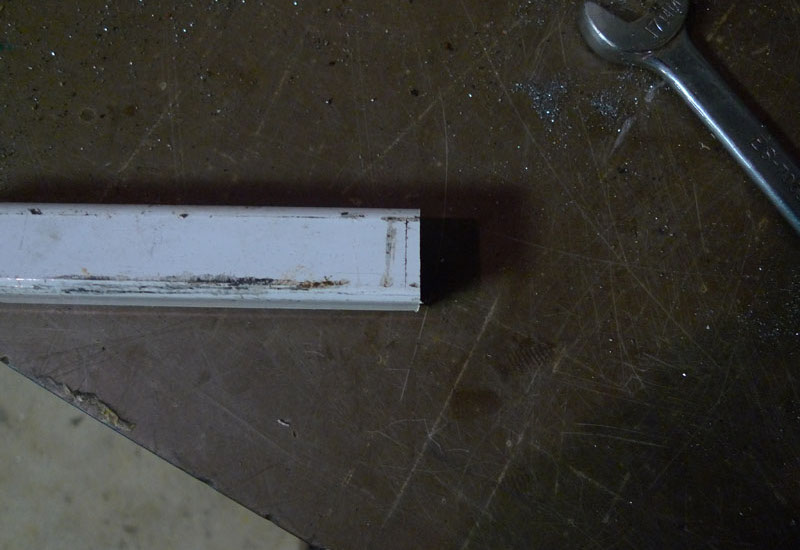

The current incarnation of the Virtual Pivot Point based Powered Egress had some issues, I decided to beef it up, upgrading from 1"x.25" steel bars to 1" square tubes. Here you can see the original design, the 5 bars on either side are 1" x 1/4". They lacked the stiffness necessary and were too narrow for the new internal locking mechanism

First I had to get my small bandsaw to cut a good square edge, above is the result after an hour of alignment and a dozen test cuts...pretty decent.

The bottom pairs of bars have an angled section to increase the width, here are the ready cuts. I found the clamps from my milling machine much easier to work with here than the built in clamp

Good Cut!

Next Piece

Here is one of them cut and both pairs of bars lined up

Both sides are cut here and lined up for spot welding against a central bar. A much beefier jig should be used here but instead of making one I was quite meticulous with my spot welds.

Clamping them to my steel / concrete workbench for final welds

Both pieces now complete

The next pair is almost the same

Both pairs now complete and laid out for comparison

The next six bars are straight shots, but everything has to be cut and measured and especially drilled with a high degree of accuracy for all the rotational points to work out well.

The old bars have all been stripped off and I've inserted two threaded rods to ensure alignment with the mounting bracket.

Now the hard parts, centering and lining up the holes. The first once just needs to be centered along the length of the tube.

Scoring and using a center punch, then starting with a very small drill bit is the best way to go. I didn't score it, but it came out very well here.

Now it's mounted onto the bike. I replaced some of the other bars for reference to make sure everything continues to line up.

The other side is done and drilled now as well. Everything still works well.

Now the next two bars are drilled, but only at the bottom, the upper two holes have to be lined up precisely with the existing pair.

Now I could have measured them in reference to the design only to find they didn't line up, or I could try to line them up with the existing bars and fail, causing it not to work. I debated this and decided to go with matching it to the existing assembly. To help with the lining up process, I screwed a long nut onto the threaded rod and in the other end a bolt, whose head I cut off. I could press this up against the bar and trace it for a good accurate alignment.

Very nice....Blue painters tape helped

Again, decent...

The two holes marked. The dabs of liquid are glue, I used a fender washer from my bearings to line up the holes so they are in the center of the tubes.

The drafters template helped find the center of the traced circle

After marking with a center punch I drilled the holes and it came out very well

Now one of those bars are mounted and everything worked out well (mounting was difficult as threaded rods are not the greatest things to slide things up and down along... a rubber mallet and alot of patience were required)

The other side is done, here the assembly is slightly raised up. Note the narrow bars are still present. They will be removed.

Another view, same thing. Looking good!

Now for the next bars. I chose to use the existing bars as guide templates.

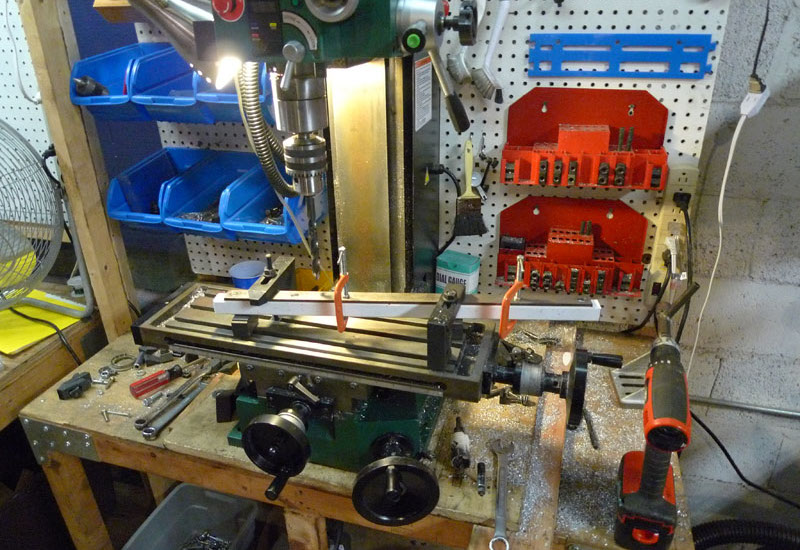

Bolting the existing bars to the new square tubes and mounting on the milling machine to ensure straight square drilling.

The next four bars are drilled and mounted. Still working great!

The last two bars were combined with the existing ones, it so happened the distance worked out perfectly. Obviously this is much heavier than necessary, but it's just a prototype...

Violla! Very Nice Very Nice...

Side View (with block of wood holding it up)

Now the actual handlebars are added

Side view with handlebars

Close up. Helped for mockup with an orange C-Clamp and the threaded rods have not yet been trimmed in length. The bars will not stay like this, I'll be enlarging the holes and welding small tubes across and inside them, and the threaded rods will be replaced with solid rods and bolts.

Fully raised up (again with block of wood helping)

Side view. A nice height here good for pulling yourself up and out with.

Now with Gas Shocks, these worked quite well at raising it, but were too strong actually to pull back down.

Looks good though. The problem was the stiffness in the upper most pair of bars that attach to the handlebars. When you pull down, the play in the bars and holes and threaded rods conspire to not close the assembly as a set of parallel bars, instead they bump into each other and stop closing. After I weld the center tubes I expect this issue to go away.

Other side, VPP raised with Gas Shocks holding it up.

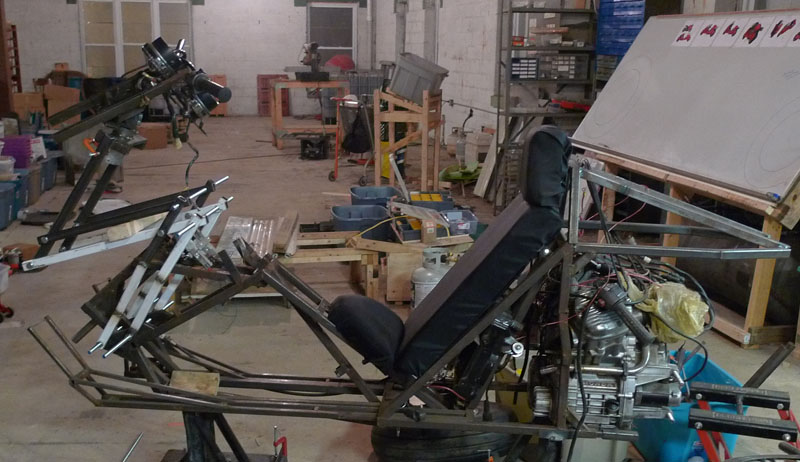

I put the front back together, and am working on the rear

Another view, the cage around the engine clamped on.

All together! Almost a rolling chassis

A sped up video assembling the bike - https://www.youtube.com/watch?v=rEs1ETbyud0

This prototype is a hard tail build, as I iron out front end issues I will probably triangulate the rear and add a simple shock.

The rear end has a lot of extra room to facilitate a gear reduction assembly (to compensate for the larger tire and greater weight)

A cool view...

Me with the prototype

Me again...

1 - 50

<

>

Launching a Kickstarter and upgrading to a new stronger stiffer virtual pivot point assembly

Help bring the fully functional high performance production Akira inspired motorcycle into existence...

Contribute through Amazon affilicate purchases

Donate directly

go to crowdfund for more options

send donations to