Welcome to Matus1976's Akira Bike Project - Building a fully functional high performance recumbent motorcycle inspired by Kaneda's ride in "Akira"

Update 14

First up, improvement on the steel rack from before. And a new workshop, 4th one.

And here I am working away in the workshop, sorting some metal.

The workshop nice and quiet

Compelling piece of evidence showing why you should wear safety gloves! This was from my angle grinder with a cut-off blade, that would have made a pretty serious cut without the textile and leather of the glove. In this case, it did not even break the skin.

I spent a good deal of time modifying my V-Strom preparing for a trip to Chicago form Connecticut, about 1,000 miles. Here is the V-Strom with a laptop/GPS tank mounted touch screen and the two Givi side cases, and a tall Givi Windscreen

The V-Strom ready for the trip, including now a Givi Top case with integrated brake lights, among many other modifications

Not more than an hour later, and less than 100 miles - this happened! I T-Boned a car doing about 30mph at an intersection, I hit the car so hard it rotated about 90 degrees. My V-Strom stopped dead, it did not flip over the car, which luckily was a low sedan and not an SUV. I was thrown over the car getting a perplexing set of injuries, I was pretty badly bruised but nothing was broken. I had quite alot of safety gear on, and hit my head hard enough to lose consciousness. I don't even recall the actual accident. My safety gear helped alot, and my modifications did as well. Within two weeks I had collected my insurance check and got another V-Strom, though this time it was the 1,000 CC version =) It took about 9 weeks to be mostly back to normal.

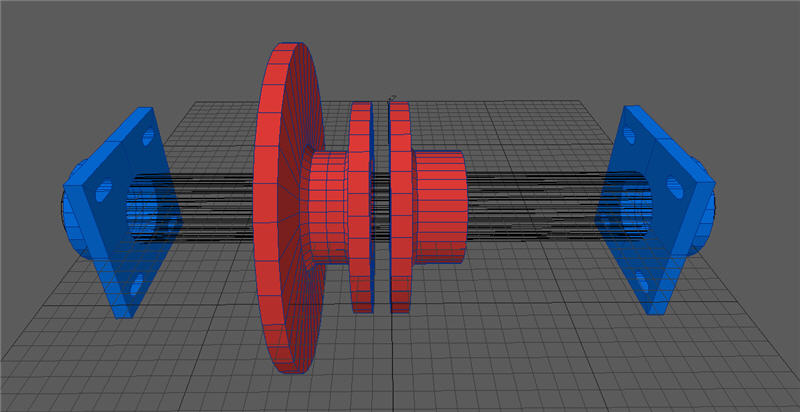

Anyway, back to the Akira Bike project! The previous entry detailed the construction of the two spindle mounts, in this entry, I worked on the two opposing hub mounts. The Blue parts are the spindle mounts, the Red are the opposing hubs completed in this update.

First, I had to cast the new hubs, and first was the smaller of the two. Here is the kiln in operation getting ready for the pour https://youtu.be/-nSYxvkm4pI

And the actual pour of the first half of the hub. Click on the image or see https://youtu.be/qmabRXnAr7g

For the next piece, I had to built an additional crucible and pour both simultaneously with a friends help. This is the largest piece I've poured yet.

The lost foam pattern for the pour, with two separate flues to facilitate both of us pouring simultaneously.

And the results. Came out very well.

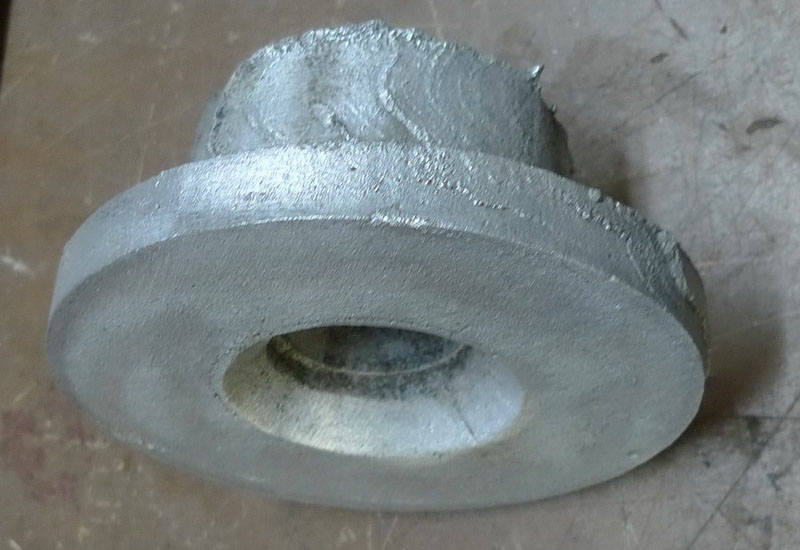

Back to the first piece. Parts are cast oversized then machined down to size.

After some cleaning

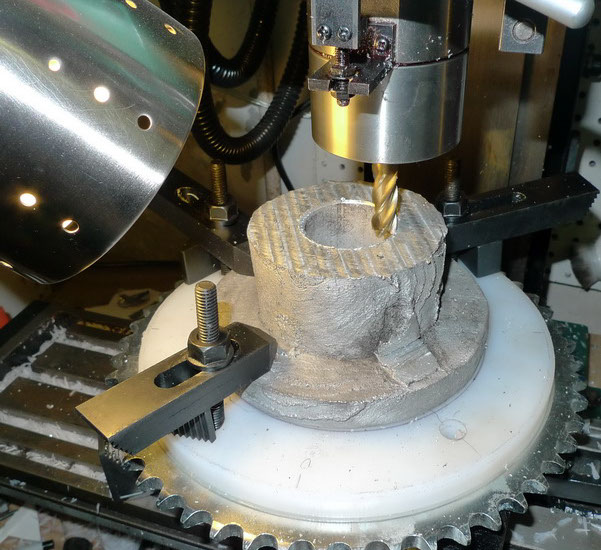

machining commences. Ignore the large sprocket, it was just a convenient mounting base.

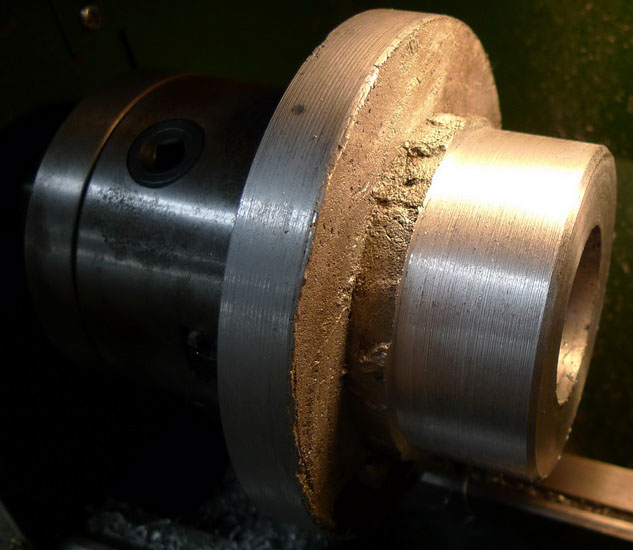

Turning on the lathe.

Working on the inner diameter on the lathe.

Checking to see if spindle fits snugly in the mount. I am using a large diameter spindle for reasons you will see later in the build

A closeup of the internal boring

A video of the lathing in action. https://youtu.be/Lvw5cDWiYVs

The finished hub mount, beautiful!

Now onto the large hub, this was the largest piece I've cast yet, and I needed someones help to pour two full crucibles simultaneously

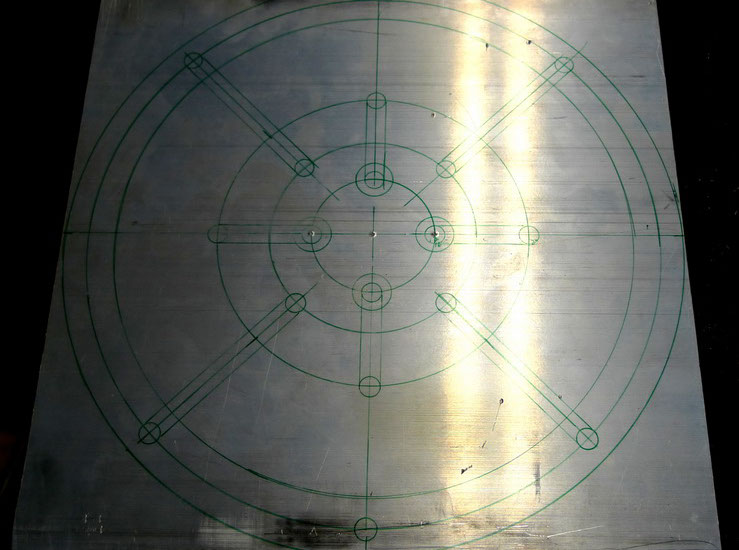

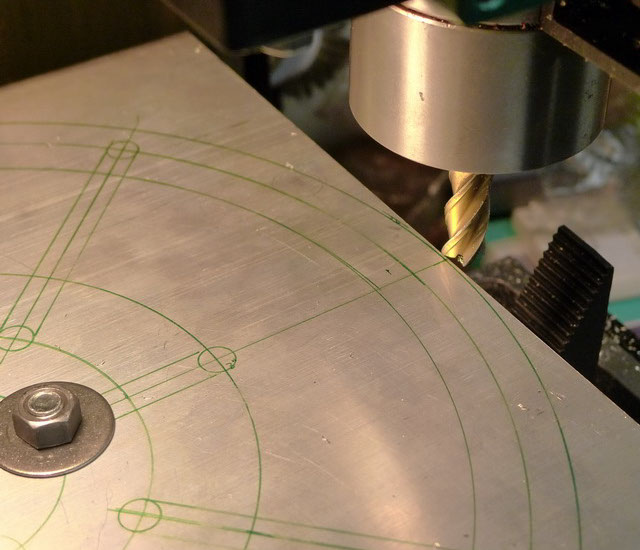

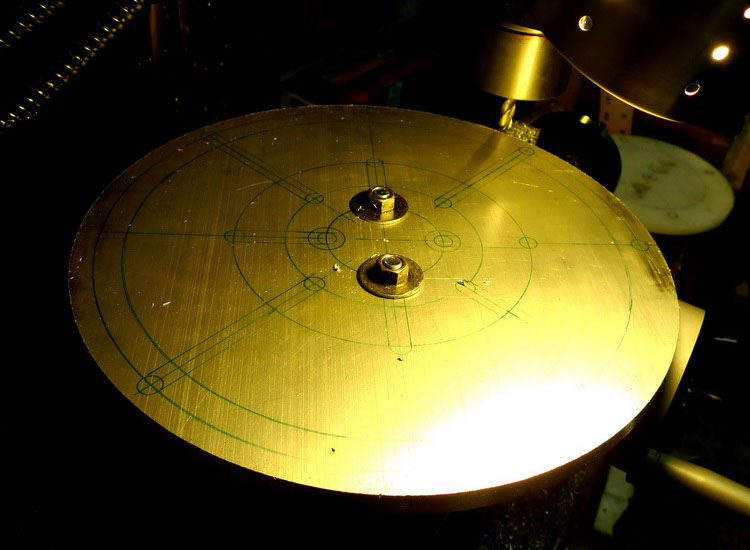

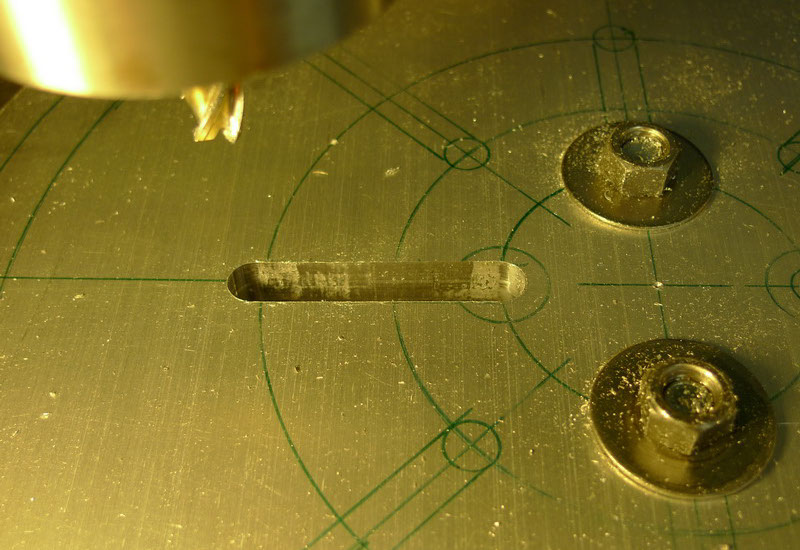

Getting ready for the milling machine...uh, that's not gonna fit on my rotary table. Time to improvise

Getting ready for the milling machine...uh, that's not gonna fit on my rotary table. Time to improvise

Getting ready for the milling machine...uh, that's not gonna fit on my rotary table. Time to improvise

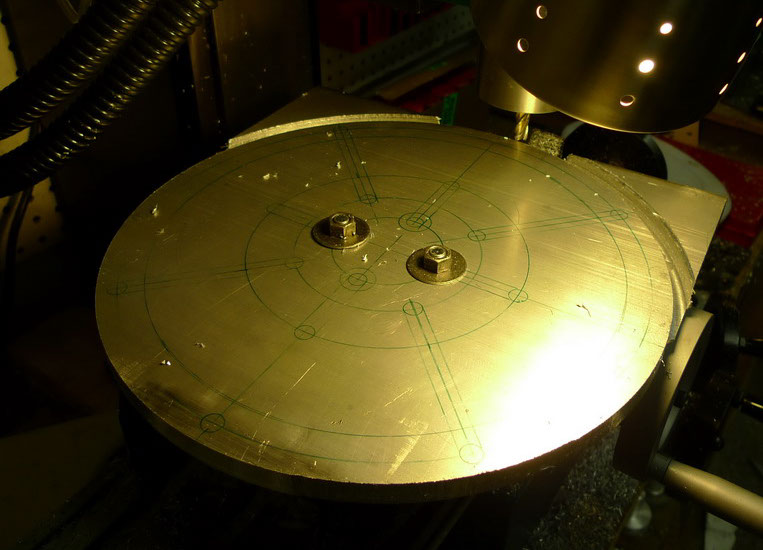

A LOOOONG time later. Hours. You can only mill small fractions of an inch at a time.

Finally the whole disc is cut out.

Now onto the grooves so I can bolt clamps to whatever part I may be working on

HOURS later. Two grooves. Thats enough for now. Now I see why I need to get a power feed mechanism ... or an assistant.

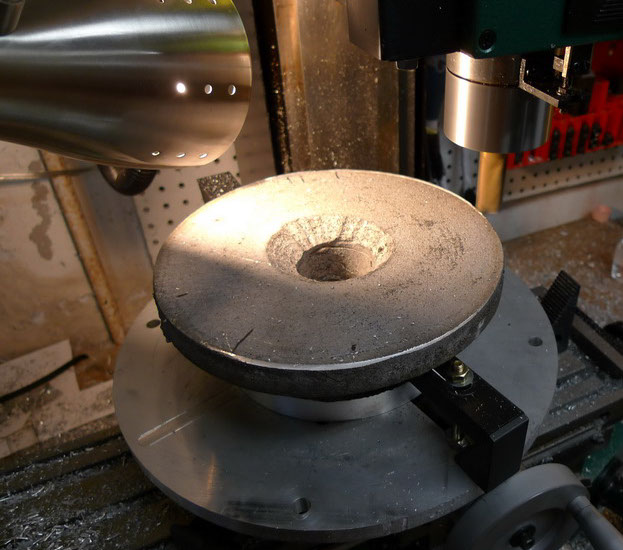

Ready to start on the hub

An assistant! Many thanks to Nick for helping out.

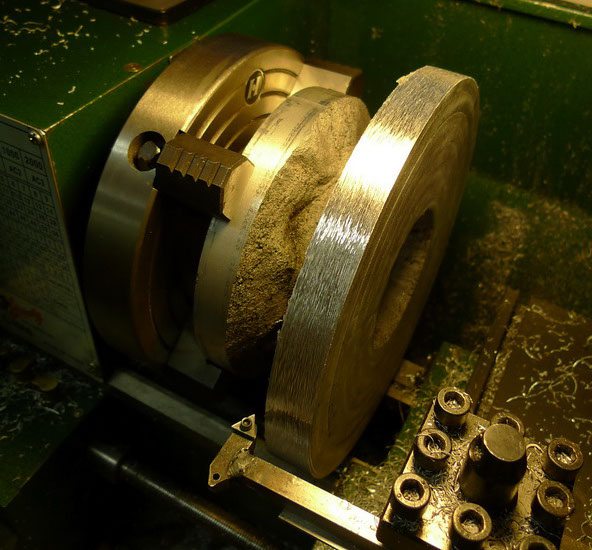

Turning the hub on the lathe, just barely fits.

Boring the interior of the hub

A closeup of the outer edge. Not great, but sufficient. See the next update for the actual rear wheel mounting.

A current progress image...

1 - 36

<

>

A motorcycle crash, and moving on to casting the rear wheel hub, the largest casting yet.

Help bring the fully functional high performance production Akira inspired motorcycle into existence...

Contribute through Amazon affilicate purchases

Donate directly

go to crowdfund for more options

send donations to